FlaSyn™ has been awarded:

1. Silver Medal at Industrial Art and Technology Exhibition (INATEX) in 2019, 2020, and 2023

2. Silver Medal at Malaysia Technological Expo (MTE) 2021

2. Silver Medal at Malaysia Technological Expo (MTE) 2021

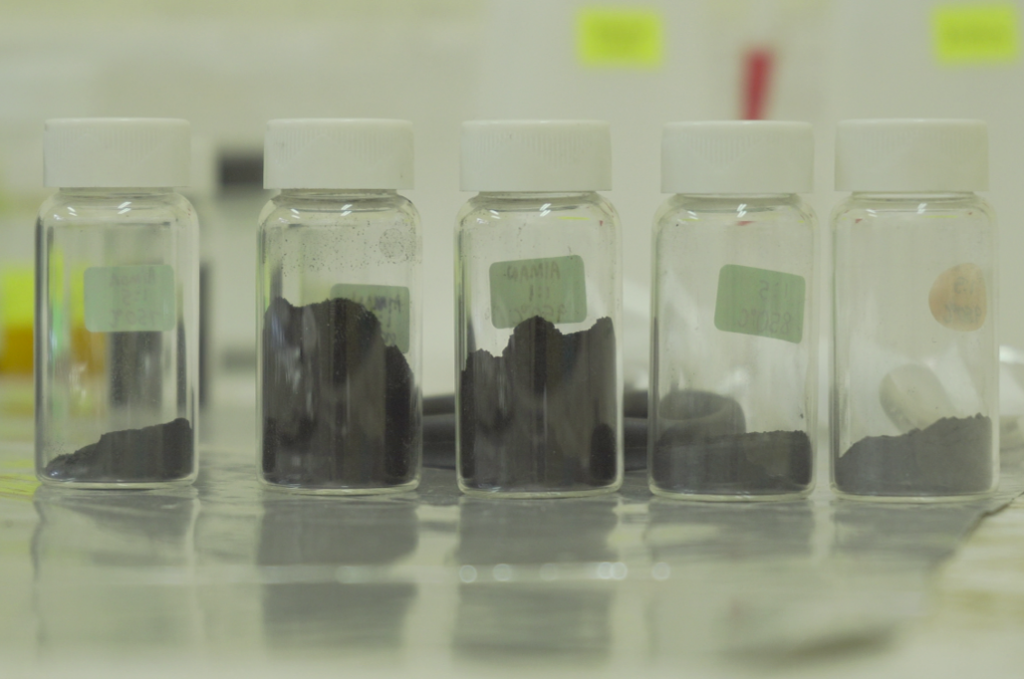

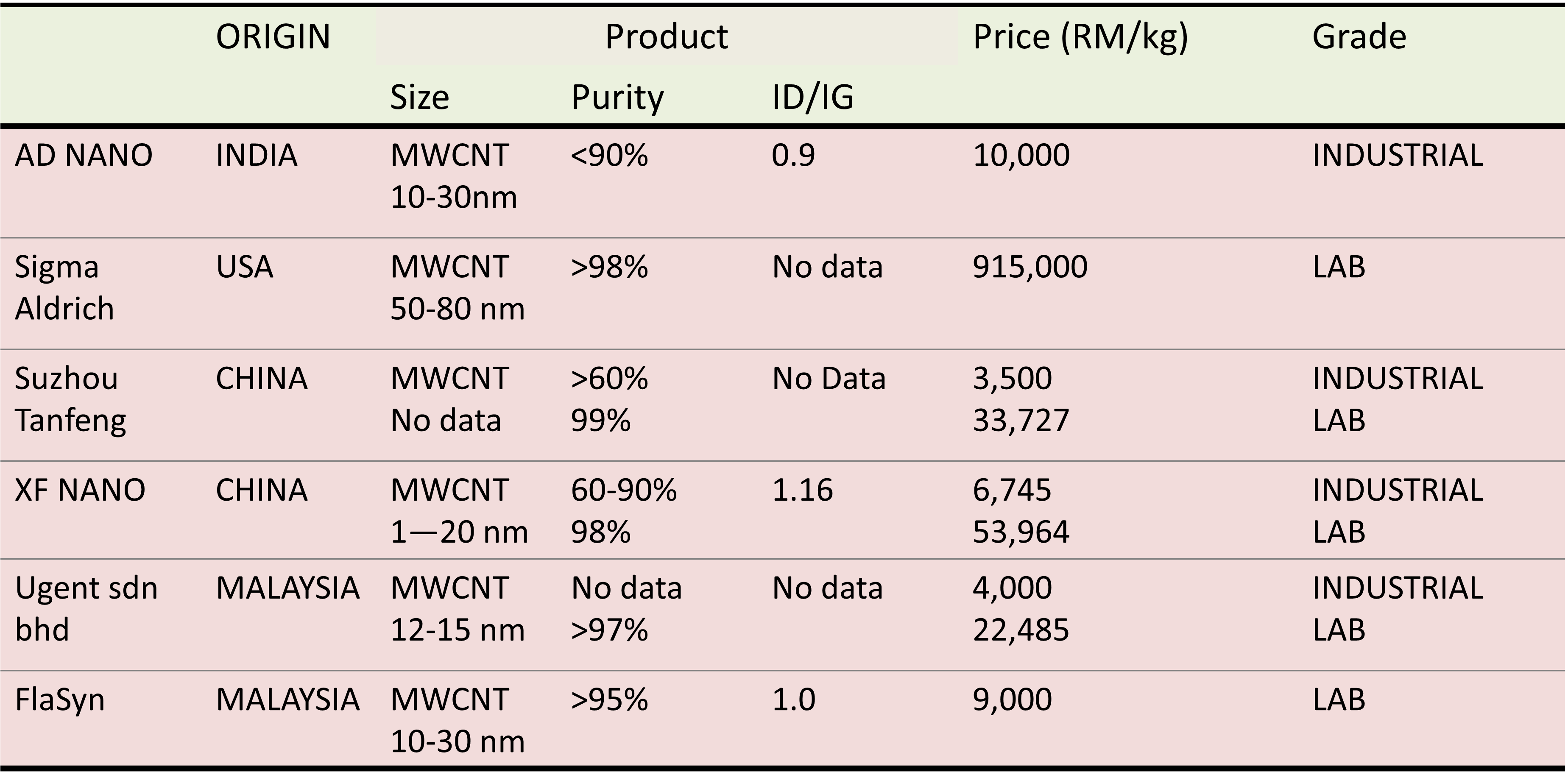

Price comparison of MWCNT in markets vs FlaSyn CNT

MWCNT improves the Mechanical Performance, Thermal Conductivity, Electrical Conductivity and permeation barrier properties of a range of composites and formulations. In purified MWCNT, the carbon nanotubes are entirely disassociated ensuring good dispersion and ease of handling while providing the full performance advantages of carbon nanotubes.

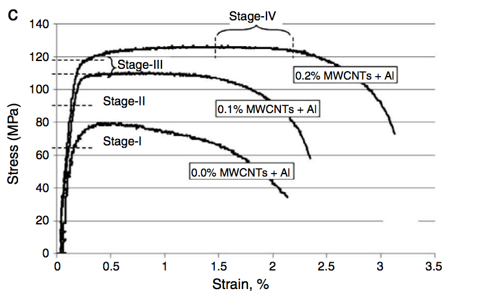

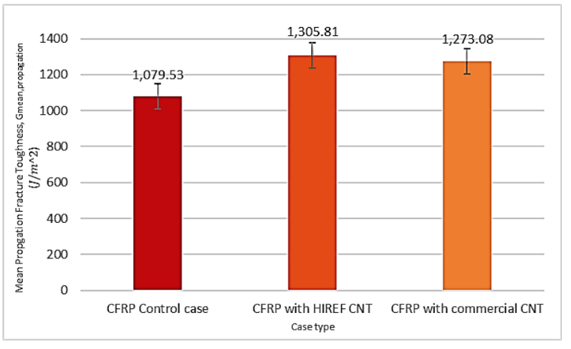

Multi-Walled Carbon Nanotubes (MWCNTs) are among the strongest known materials and can be used as additives to enhance the strength of other materials. Numerous studies have shown that graphene and its derivatives, when incorporated into composites, offer tremendous potential due to their exceptional reinforcement properties.

The addition of a small amount of MWCNT or MWCNT-based masterbatch to a polymer matrix can significantly enhance its mechanical properties. We are suppliers of Multi-Walled Carbon Nanotubes.

The precise addition of MWCNTs or their variants to a matrix results in a well-dispersed nanocomposite, significantly enhancing its electrical properties.

MWCNT is one of the most thermally conductive materials in the world. Even a small addition of MWCNT or its variants can significantly improve thermal conductivity. We are suppliers of Multi-Walled Carbon Nanotubes.

MWCNTs are significantly stronger than steel, with electrical conductivity comparable to copper, excellent thermal conductivity, and a lightweight structure. Even a small incorporation or coating of MWCNTs with metals or metal alloys enhances their properties. HIREF manufactures MWCNT-based metal nanocomposites and anti-corrosive paints.

Incorporating MWCNT samples into molten metal through stir casting can enhance the material’s thermal properties.

Numerous researchers have demonstrated that incorporating a small quantity of MWCNT into metal can significantly enhance its electrical conductivity. We are suppliers of Multi-Walled Carbon Nanotubes.

MWCNT Based paint can improve the shell life of metal. protecting it from corrosion.

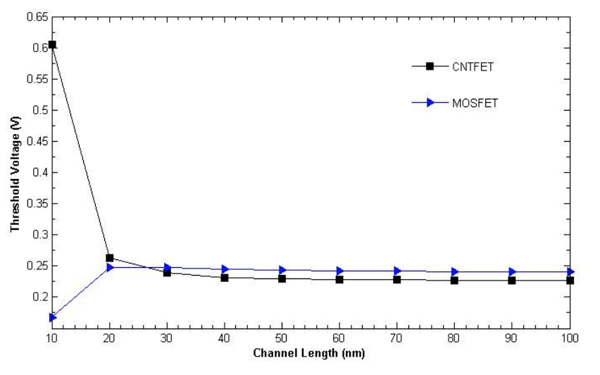

MWCNTs has very good electrical conductivity and also Thermal Conductivity due to which it has purse a wide range of applications in the field of Electronics such as Printable Electronics, Sensors, Displays and Hard disk component handling.

MWCNT-based circuits enable high-speed manufacturing processes, provide transparent conducting electrodes, and are an excellent candidate to replace Indium Tin Oxide (ITO).

Provide consistance in performance

It offers consistent ESD protection, extended carrier life due to the durability of additives, high cleanliness with ultra-low particulate levels, flexible and durable printing capabilities, and easy scalability.

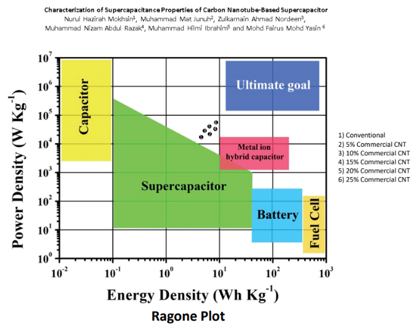

MWCNTs are among the leading materials used to enhance the efficiency and sustainability of modern energy sources. Their applications range from batteries, supercapacitors, and fuel cells to wind turbines and solar cells, offering increased power output and reduced recharging times.

Achieve enhanced power and energy density as a result of the increased surface area.

Coating electrode surfaces with MWCNTs will provide the desired performance improvements.

More electricity can flow between the electrodes and the chemicals inside the battery.

MWCNT-based dispersions enhance paints and coatings by improving mechanical properties, scratch resistance, flexibility, abrasion resistance, and conductivity. They also boost decorative effects, adhesion, and pencil hardness, all while having minimal impact on color and offering a cost-effective solution.

Incorporating MWCNT dispersion into samples improves mechanical properties such as scratch resistance, flexibility, abrasion resistance, and pencil hardness.

Achieve uniform conductivity in primer with a minimal loading of MWCNT variants, ensuring efficient performance with reduced material usage.

MWCNT-based paint can enhance the protective coating of metals, shielding them from corrosion effectively.

Incorporating MWCNT or its variants into concrete can control material behavior and introduce novel properties, such as enhanced mechanical performance and durability. This can lead to features like self-sensing capabilities, self-cleaning, self-healing, high ductility, and self-regulation of cracks.

Even a minimal incorporation of MWCNT in concrete can significantly improve its self-sensing capabilities, self-cleaning, self-healing, high ductility, and self-control of cracks.

MWCNTs enhance concrete by improving its bulk properties, increasing tensile strength, and eliminating the need for superplasticizers, ultimately reducing costs per building site.

It is evident that the use of nanomaterials in concrete significantly improves the technical properties of cement-based materials, enhancing performance and durability.

Yield strength +77% Tensile strength +52% Hardness +44%

Power density +212% Energy density +84%

HiREF CNT content +0.1% Hardness +17%

Threshold increase <20nm